Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

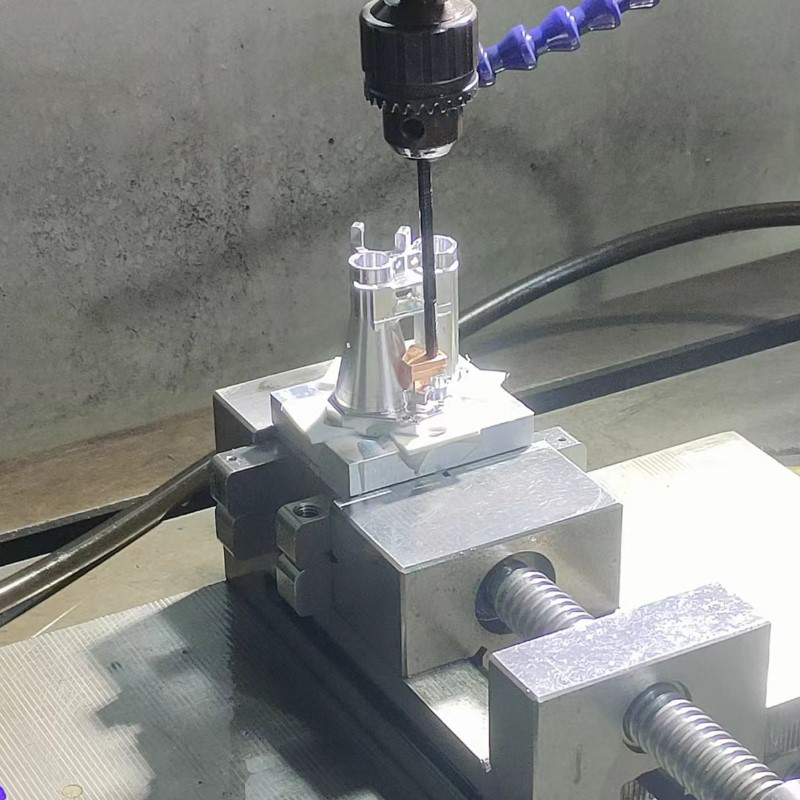

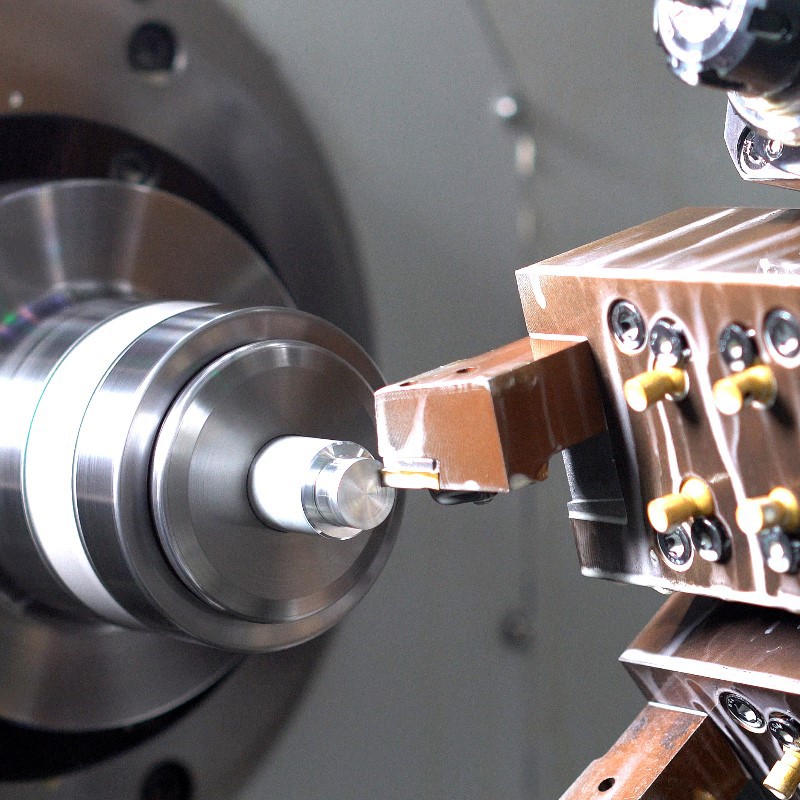

EDM Services

At Future Parts, we offer advanced cutting solutions to provide you with precision machined parts that are perfect for complex geometries. Our state-of-the-art CNC machining capabilities ensure high precision with tolerances as tight as +/- 0.0001 inches. With our auto threading feature and enhanced thermal stability, we can deliver consistent and reliable results.

EDM

We have electrical discharge machining (EDM) capabilities suitable for producing deep pockets, creating complex features, and cutting the hardest metals with great precision.

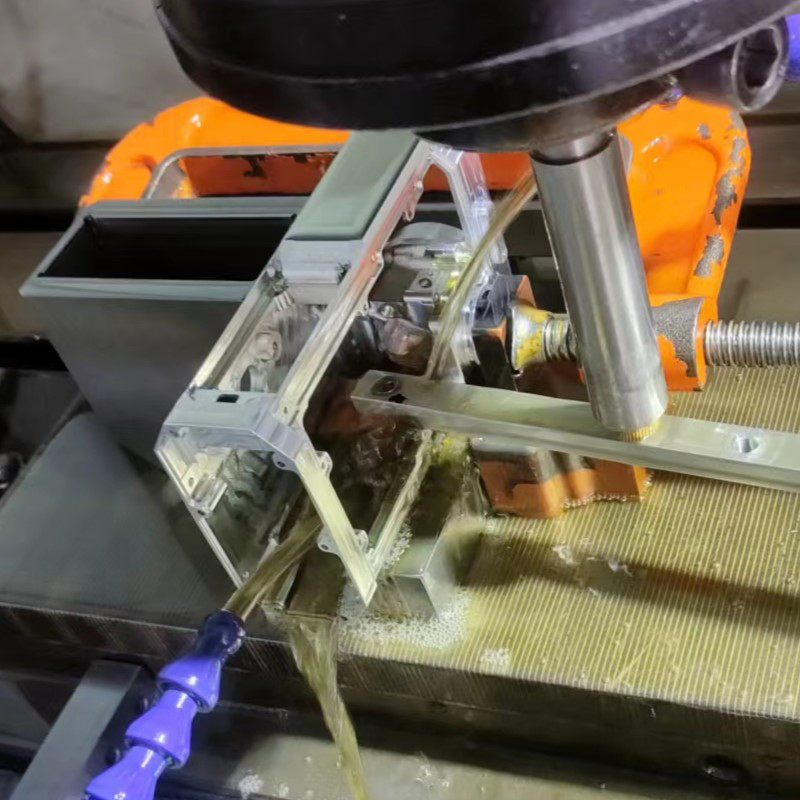

Wire EDM (Electrical Discharge Machining) stands out as a subtractive manufacturing marvel. It’s a technique where electrical sparks shape and carve through conductive materials. What sets Wire EDM apart? Its unmatched precision. Using a fine electrically charged wire—normally brass or copper—guided by advanced CNC systems, the process meticulously erodes materials, achieving intricate and accurate designs.

Metal Materials for Wire EDM

Common materials including: aluminum, copper, brass, steel, titanium,bronze, and other conductive materials(like gold, silver, nickel alloys, etc).

Surface Finishing for Wire EDM

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

|

Name

|

Decsription

|

Materials

|

Color

|

Texture

|

|

|

Anodizing

|

Anodizing improves corrosion

resistance, enhancing wear

resistance and hardness, and

protecting the metal surface.

Widely used in mechanical parts,

aircraft, and automobile parts,

precision instruments, etc.

|

Al uminum |

Clear, black, grey,

red, blue, gold.

|

Smooth,

matte finish.

|

|

Bead Blasting

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Matte

|

|

Powder Coating

|

Powder coating is a type of

coating that is applied as a free- f lowing, dry powder. Unli ke conventional liquid paint which is delivered via an evaporat ing solvent, powder coating is |t ypically applied e lectrostatically and then cured under heat or with ultraviolet 1 ight. |

Aluminum,

Stainless Steel,

Steel

|

Black, any RAL code

or Pantone number

|

Gloss or

semi-gloss

|

|

Electroplating

|

Electroplating can be functional,

decorative or corrosion-related.

Many industries use the process,

including the automotive sector,

in which chrome-plating of steel

automobile parts is common.

|

Aluminum, steel,

stainless steel

|

N/A |

Smooth, glossy

finish

|

|

Polishing

|

Polishing is the process of

creating a smooth and shiny

surface, either through physical

rubbing of the part or by chemical

interference. The process produces

a surface with significant

specular reflection, but in some

materials can reduce diffuse

reflection.

|

Aluminum, Brass,

Stainless Steel,

Steel

|

N/A |

Glossy

|

|

Brushing

|

Brushing is a surface treatment

process in which abrasive belts

are used to draw traces on the

surface of a material, usually for

aesthetic purposes.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Satin

|

|

Painting

|

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

|

Aluminum, Stainless Steel, Steel

|

Custom |

Gloss,

semi-gloss, flat, metallic, textured |

|

Alodine

|

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

|

Aluminum

|

Clear, Gold |

Same as before

|

|

Part Marking

|

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

|

All materials

|

Custom |

N/A

|

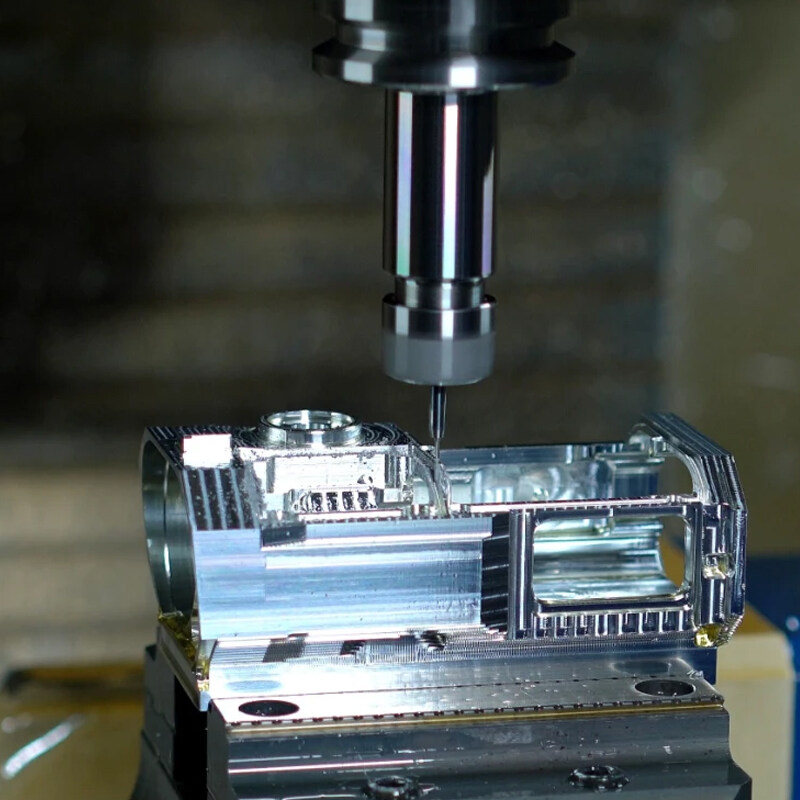

Specification

|

Capability |

Details/Specifications |

|

Material Compatibility |

Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

|

Tolerance |

Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

|

Cutting Speed |

Up to 300 mm2/min (specific to material and thickness) |

|

Surface Finish |

As fine as Ra 0.2 µm |

|

Maximum Cutting Thickness |

Up to 12 inches (300 mm)–varies based on material |

|

Wire Diameter Range |

0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

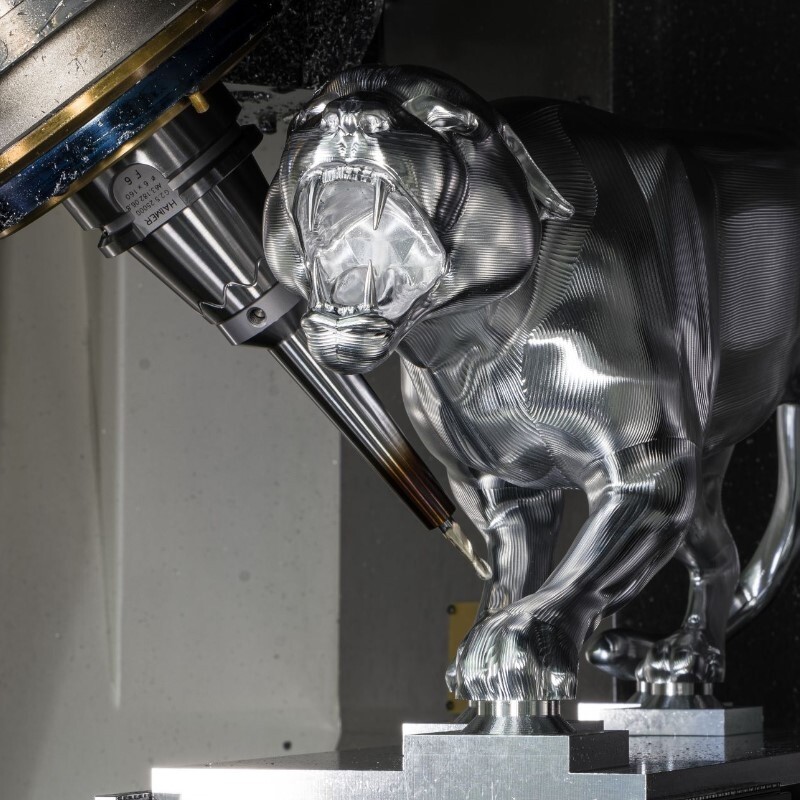

Applications of Wire EDM Machined Parts

Aerospace: Propel aerospace innovation with our Wire EDM services, crafting components that not only achieve lightweight properties but also uphold the highest standards in strength, meeting the rigorous demands of aviation.

Medical: We not only prioritize precision but also adhere to the strictest cleanliness standards essential for medical applications, ensuring reliability in critical scenarios.

Automotive: Elevate your automotive components' performance and durability through our Wire EDM precision. Our accurate machining processes contribute to enhanced efficiency and resilience in automotive applications.

Electronics: With our Wire EDM services, we guarantee components that not only meet but exceed the highest standards, ensuring optimal performance and reliability in electronic applications.

Manufacturing: Transform your manufacturing processes with our Wire EDM capabilities, delivering intricate and precise tool and die components. This precision contributes to the seamless functioning of your manufacturing operations.

Energy: Power up your energy components with our Wire EDM services, ensuring not just efficiency but also reliability. Our precision machining plays a pivotal role in optimizing energy-related components for peak performance and longevity.